Process Of Making Paper Money

/chinese-golden-paper-money-for-the-gods--heaven-used-money-683239956-5bfd92e946e0fb002642d92b.jpg)

While most paper used for such items as newspapers and books is primarily made of wood pulp the currency paper made specifically for the bureau of engraving and printing bep is composed of 75 cotton and 25 linen with the security thread and watermark built in.

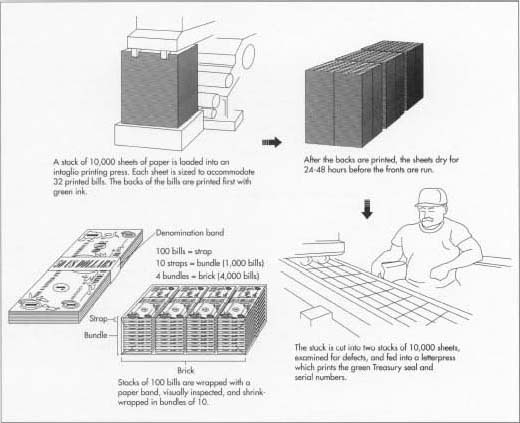

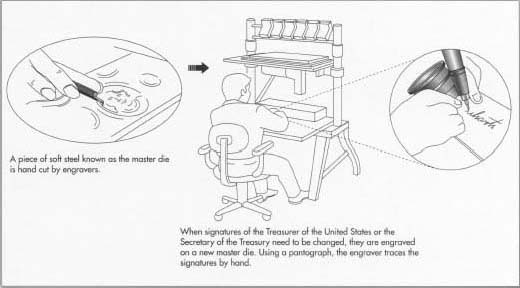

Process of making paper money. What is paper money made out of paper and ink. European explorers like marco polo introduced the concept in europe during the 13th century. Now the paper money is printed in various ways with a number of different types of machines. Making paper money making paper money is a complex procedure.

The government employed graphic artists are the ones who design and make the templates that are either accepted or rejected by the government mints. Start the process by dying paper or choosing to use brightly colored sheets. Now let s explore the process of making money from the design to the distribution. The paper also known as the substrate is a special blend of 75 cotton and 25 linen to give it the proper feel.

Wouldn t be your first guess right. However you must carefully follow all legal rules and regulations when preparing your own play money. Fake money is a great prop for games educational exercises and stage performances. Bureau of engraving and printing makes paper money or dollar bills.

Paper currency first developed in tang dynasty china during the 7th century although true paper money did not appear until the 11th century during the song dynasty the usage of paper currency later spread throughout the mongol empire or yuan dynasty china. Because of the high price of cotton in 2010 the cost of making a note increased 50 from what it cost in 2008 according to the same article. The paper used to make money in the united states is made out of 75 cotton and 25 linen according to cnn money. Most of the steps are designed to make the money difficult to counterfeit.

Then design the currency details by hand or by downloading a money template. With paper money the materials are as important as the manufacturing process in producing the final product. Modern papermaking methods although significantly more complicated than the older ways are developmental improvements rather than entirely new methods of making paper. Essential to the process are the fibers which are never totally destroyed and when mixed and softened form an interlaced pattern within the paper itself.

Paper money takes the load off. Mint makes coins while the u s. The paper a sort of promissory note could then be traded for goods and the seller could go to the agent and redeem the note for the strings of coins.

/GettyImages-1054017850-0c7ca7d8368c4ab681a3d9c0fd2892e8.jpg)