Process Of Making Paper From Wood

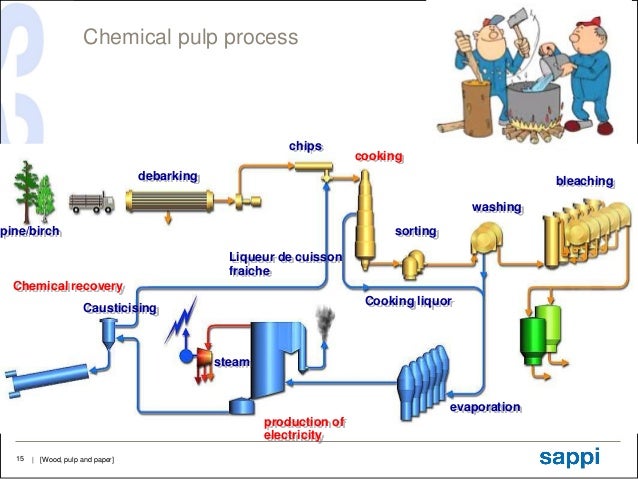

This innovation ended the nearly 2 000 year use of pulped rags and start a new era for the production of newsprint and eventually almost all paper was made out of pulped wood.

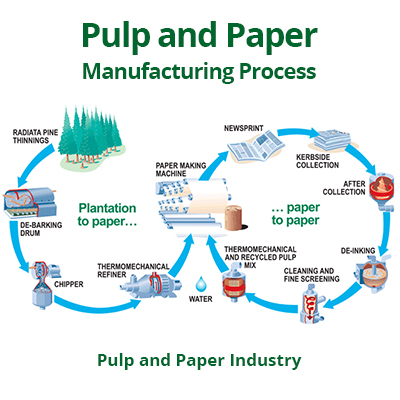

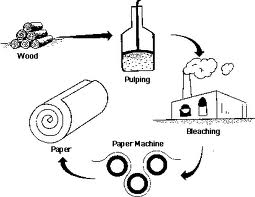

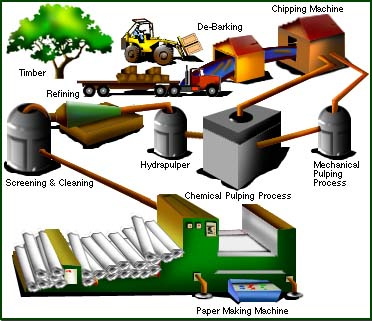

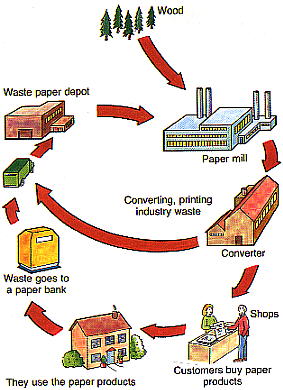

Process of making paper from wood. Enjoy the videos and music you love upload original content and share it all with friends family and the world on youtube. In 1844 canadian charles fenerty and german f g. Steps in the pulp and papermaking process raw material preparation wood received at a pulp mill may be in several different forms depending on the pulping process. Paper loses its glue like substance every time it goes through the paper making process so when making paper new wood pulp must be added in.

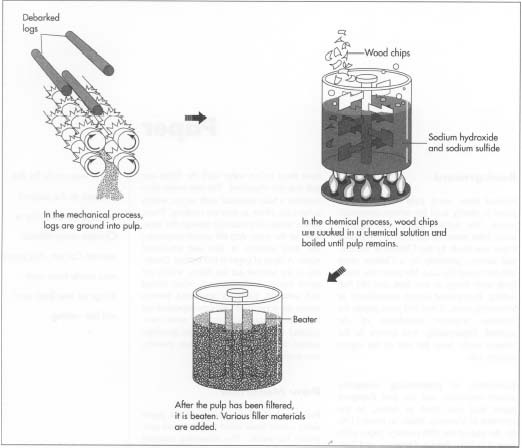

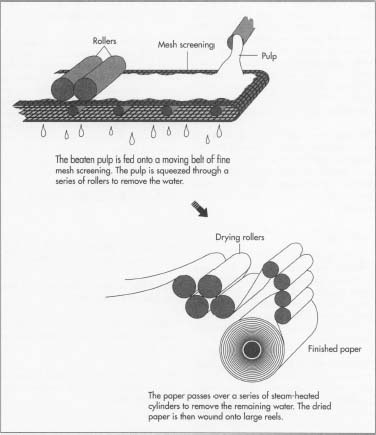

In the mechanical process logs are first tumbled in drums to remove the bark. Collect process and bum lignin and waste wood to produce energy. For most hobby makers this will be your kitchen sink a washing up bowl or a large plastic tank. While the process will result in an unrefined quality and may be rather heavy you can still have a lot of fun experimenting with different kinds of wood until you find your ideal recipe.

Step 1 choose what kind of wood you want to use to make your paper. That pulp can come from newly cut trees or from used paper which is processed to recapture the pulp. Keller had invented the machine and associated process to make use of wood pulp in papermaking. The actual act of making a sheet of paper by hand requires a vat mold and deckle.

The vat is the container the pulp floats in. And remove and treat wastes from process water for release into the environment.