Process Of Making Paper

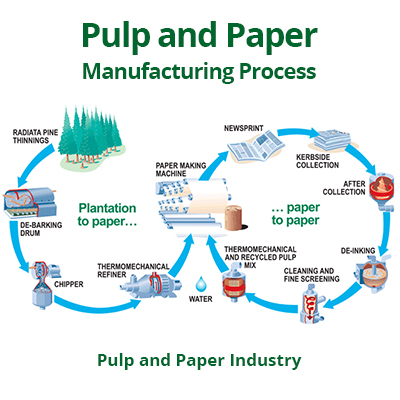

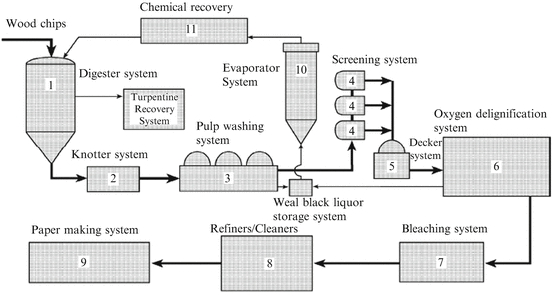

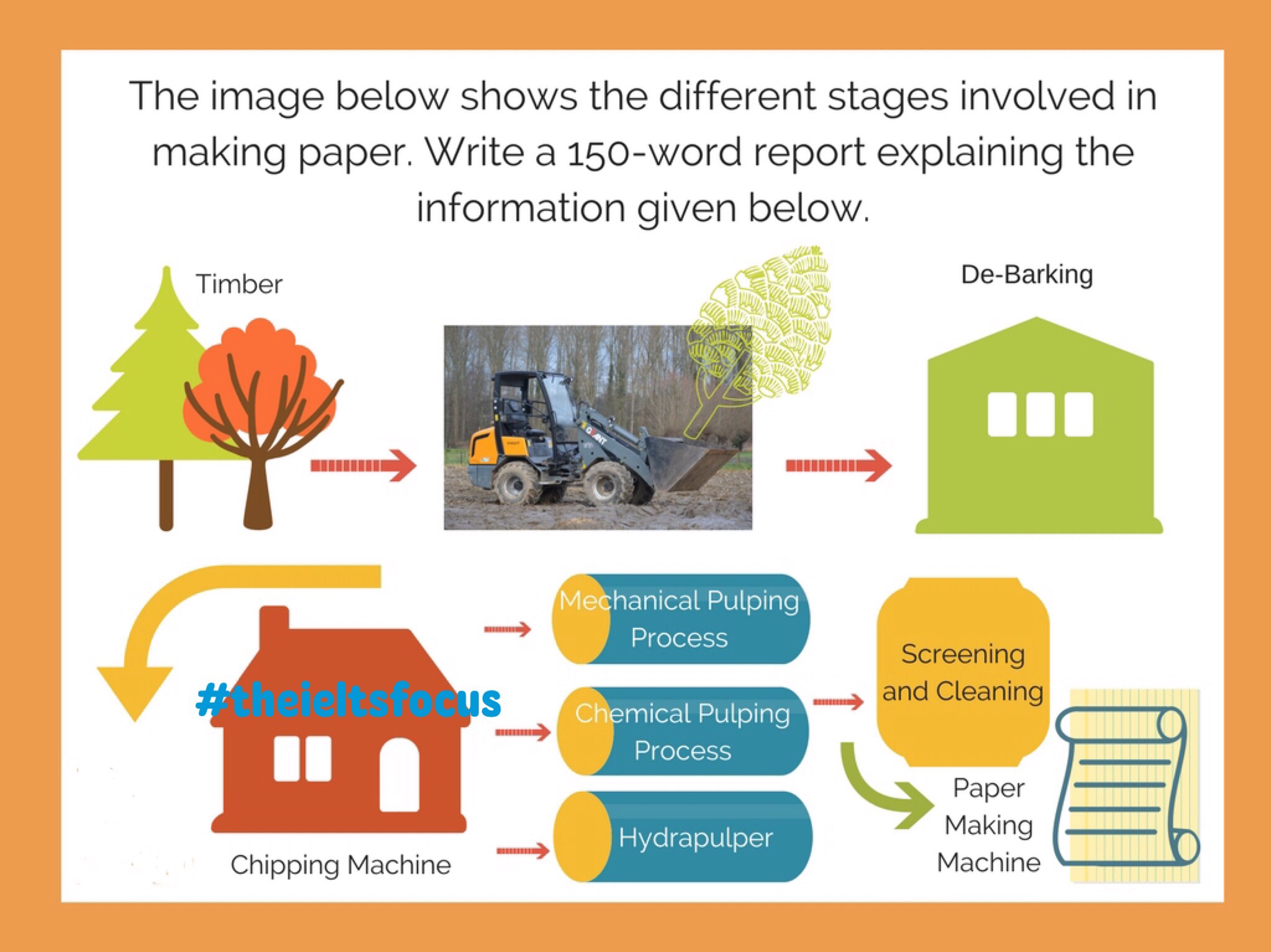

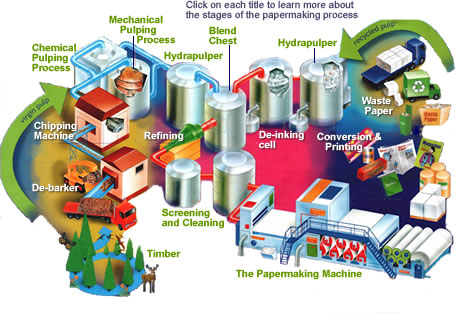

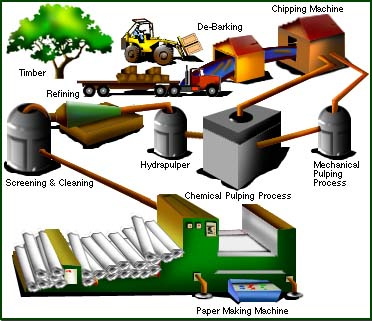

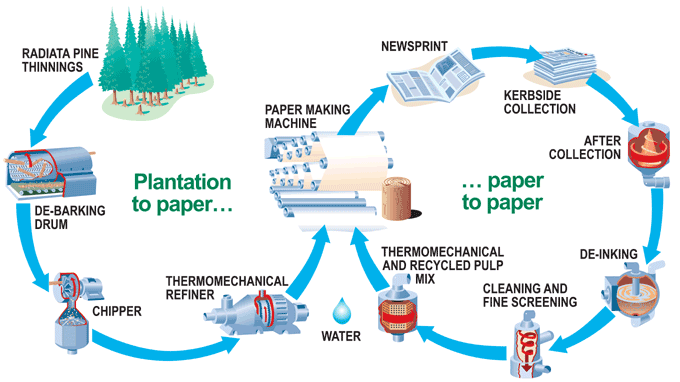

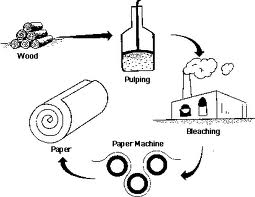

The steps in the process are as follows.

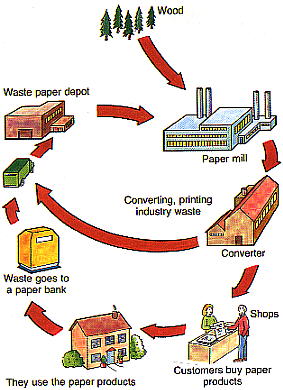

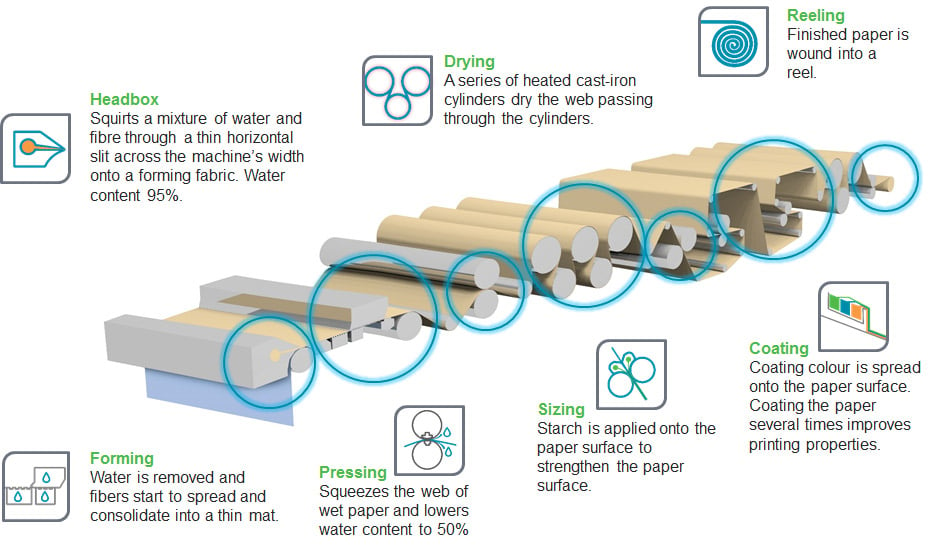

Process of making paper. In the paper making process the dilute stock passes through a headbox that distributes the fiber slurry uniformly over the width of the paper sheet to be formed. Sappi is a global company focused on providing chemical cellulose paper pulp and paper based solutions to its direct and indirect customer base across more. In this article i will explain how easy it is to make paper using a very simple process that utilizes tools readily available in the market or even at home. It s fun straight forward and you help protect the environment by recycling your own paper.

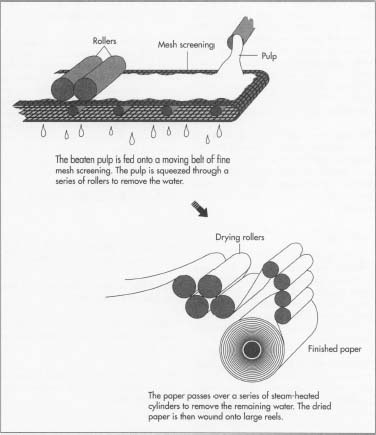

2 identical picture frames. Paper making a process that s thousands of years old is a fun project for kids and adults alike. 2 the paper stock is filtered on a woven screen to form a matted sheet of fibre. 3 the wet sheet is pressed and compacted to squeeze out a large proportion of water.

Papermaking is the manufacture of paper and cardboard which are used widely for printing writing and packaging among many other purposes today almost all paper is made using industrial machinery while handmade paper survives as a specialized craft and a medium for artistic expression. The basics of paper making are simple and it s also an eco friendly way to recycle old paper products. Once it is on the felt sheet let it dry. Essential to the process are the fibers which are never totally destroyed and when mixed and softened form an interlaced pattern within the paper itself.

Making paper is also a great crafts project to do with kids at home. To make paper you will mix pulp and water then pour it onto a piece of window screen. If you want to speed things up you can put in the microwave for one minute. Your paper should peel off completely from the screen sheet.

The paper you can make at home will have an interesting texture and is great to use for art projects or stationery. Then let it dry for 12 15 hours. The web of fiber that will make the new paper sheet is formed on a continuously moving pulp. 1 a suspension of cellulosic fibre is prepared by beating it in water so that the fibres are thoroughly separated and saturated with water.

Repeat this process for every sheet of paper that you want to make. In papermaking a dilute suspension consisting mostly of separate cellulose fibres in water is drained. If you re a grade school teacher making paper works as a great hands on learning experience for young students. In the second stage after refining the pulp is screened cleaned and most of the process water is removed in preparation for paper making.

Bleaching process raw pulp contains an appreciable amount of lignin and other discoloration it must be bleached to produce light colored or white papers preferred for many products.